FREQUENTLY ASKED QUESTIONS

Yes, for best performance you should carry out the bedding process. After installation of your Ksport brake system it is highly recommended to follow this procedure:

- The brakes should feel smooth without any vibrations. If you feel any vibration, immediately stop the vehicle and re-check your installation.

- On a remote road with no traffic accelerate to approximately 30-45mph and perform at least 10 brake applications using 3 second durations at least ¼ mile apart using light to medium pressure.

- This process will gradually increase the brake pad and rotor temperature which allows the brake pad and disc to mate with the proper friction.

- When the above process is completed the brake system is ready for normal use.

No. Cross drilled rotors can experience slight surface cracks over time. This is the same with all companies that produce cross drilled rotors.

Yes, our kits are designed to work with OEM Master Cylinders.

No, you can purchase our front and rear brake kits individually. Most OEM proportioning valves are set to distribute brake force appropriately. Simply upgrading to a larger brake kit will improve stopping distance and pedal feel.

Yes, all OEM ABS systems will still function with any of our brake systems.

As a general rule of thumb, adding approximately 4″ to the rotor size will help you determine the required wheel size for clearance. For example, most 13″ big brake kits require 17″ or larger wheels. Our team is more than happy to assist with determining which brake system is right for you. We can provide templates that allow you to test fit our calipers and determine If they will clear your wheels. If you need a specific template, please contact our team. You can also check out our Step by Step Guide on Measuring your Wheel for Brake Clearance.

We generally keep most of our brake pads in stock. You can order them directly from us, or, there are several other brands that cross reference ours such as AP and Ferodo. If you have a specific brand in mind or other questions, please feel free to contact us.

If you measure your rotors and determine that the thicknesses is at or below the measurements below, please contact us to order a new set of rotors.

- 286mm rotor = 23mm

- 304mm rotor = 25mm

- 330mm rotor = 29mm

- 356mm rotor = 29mm

- 380mm rotor = 29mm

- 400mm rotor = 33mm

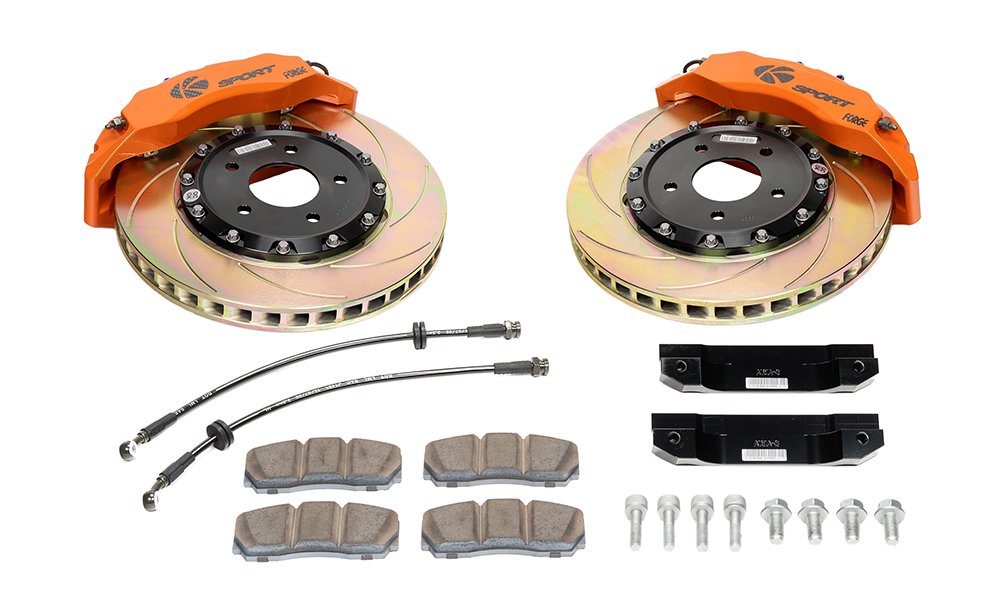

Two-piece rotors provide light weight, fade-free performance and effective grip on the racetrack as well as comfortable, easy-to-use operation under normal driving conditions. The rotor design is extremely lightweight when compared to OEM one-piece rotors, commonly weighing up to 50% less than OEM rotors of the same size.

Lightweight center sections crafted from 6061-T6 aircraft-grade aluminum give you the benefit of lower rotational mass – making wheels easier to stop and giving you the instant snap of brake response that’s proper for high performance driving. Because the outer section of the two-piece rotor can expand and contract independently from the center section, chances of the entire rotor warping due to heat buildup are greatly reduced. And, since aluminum is a better conductor of heat, the center sections serve as effective heat sinks by passing heat away faster to the air and to the hub assembly. Combined, these two factors give them a much longer service life than traditional one-piece rotors.

Slotted rotors feature grooves on the rotor surface to wipe away heat, dust, and gases. Because of this, we recommend slotted rotors for vehicles that will be seeing more track use. Cross Drilled rotors are recommended for daily driven vehicles since they tend to run cooler than slotted. Both rotor types have increased “bite” over stock and continuously clean and refresh the pad surface.

Yes. All Ksport brake kits are available with several customization options. The calipers come standard in painted colors such as Orange, Red, Black and Yellow. We also offer an option to upgrade to premium high polish finishes as well as Glassy/Hard Anodized Colors. With over 20,000 custom color finishes available the options are nearly limitless.

Options to upgrade to a Titanium Center Bell and Hardware or Twin Color Anodized Center Bell are also available for further customization of your brake system.

The floating rotor features an outer section designed to shift slightly as needed. This allows for better self-centering in the caliper which lowers brake drag and boosts performance through more even application. This is ideal for a serious track driver that’s mindful of avoiding temperature buildup that commonly causes brake fluid boiling and pedal fade.

Some brake noise is common with big brake kits. The noise is caused by the pad and rotor material and does not signify any defects. Most aftermarket big brake kits do make some noise intermittently until they are warmed up.

Big brake kits can be installed on the front and the rear. We recommend doing all four wheels, but it is possible to install on the front only. We do not recommend installing on the rear only as the front does more of the braking than the rear which can cause a braking imbalance.

TECHNICAL GUIDES

WARRANTY & SERVICE

To begin a warranty claim or send your product in for service, please begin by downloading and filling out our warranty/service form below.

Once you have completed the form, please either fax it to 480-829-8103 or submit it via our contact form here. A Ksport USA staff member will contact you within 1-2 business days regarding your warranty or service request.